What is hysteresis?

In our previous article, we looked at the material modes of failure we need to be aware of in engineering. In this article we’re going to dive into elastic and magnetic hysteresis.

Elastic Hysteresis

Elastic hysteresis is the difference in strain of a material during loading of stress or strain, versus during the unloading of strain or stress on the material.

If we imagine a piece of rubber hanging from a hook. As we load weights onto the rubber, it will extend by a certain amount for each additional weight that we add. Let’s say we mark the position of the rubber after each weight that we’ve added:

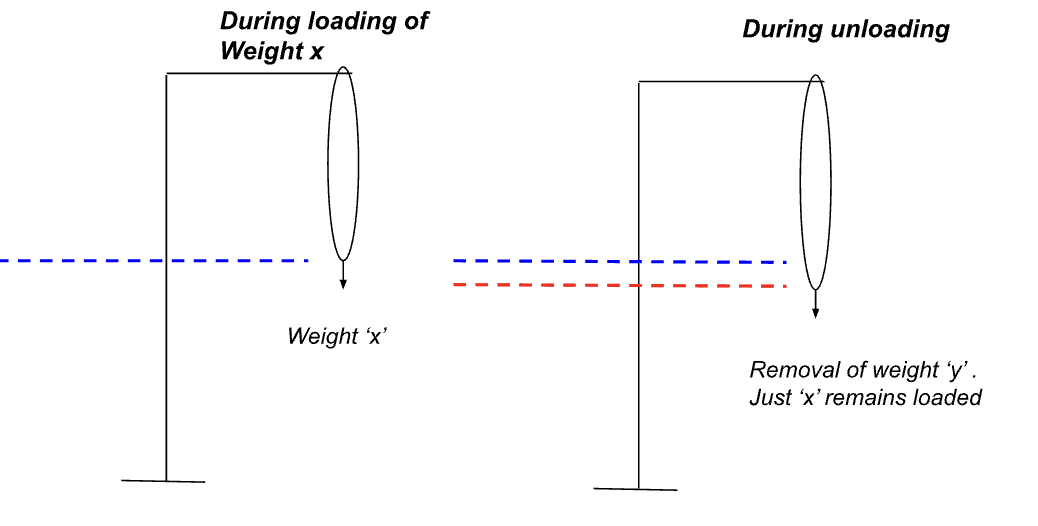

If we start to unload the weights again, one by one, we would expect to see that the rubber returns to each of those positions as we unload the related weight. However, what we actually see is that the rubber doesn’t contract by the same amount it was extended by for that weight:

In this diagram:

- The blue line shows the length of the rubber with a weight acting on it during the loading phase. In other words, the position of the rubber when we add weight.

- The red line shows the length of the rubber with a weight acting on it during the unloading phase. In other words, as we take off the weight.

The elastic hysteresis is more pronounced when the loading and unloading is done quickly, rather than when it is done more slowly. The difference between the blue and red line is known as hysteresis.

If we think of it in terms of force, we can say the rubber required more force for a given stretch during loading, compared to during unloading. We can show this effect on the stress strain diagram:

The curves in the diagram show that strain doesn’t change instantaneously with stress. Instead, it lags behind it. This ‘lagging’ of strain is known as hysteresis, and the closed curves shown are referred to as a hysteresis loop.

If you’ve read our previous article where we discussed toughness, you’ll remember we mentioned that the area underneath the stress-strain curve is the total energy absorbed by the material. In the situation above, we can see that the total energy absorbed during loading is greater than the total energy released during unloading.

The area between the curves, gives the difference between the energy absorbed and energy released by the material. This difference is due to energy being dissipated in other forms (such as heat loss). This is significant for engineering applications. If we think of an application where we would want a material to ‘use up’ or lose energy, we would pick a material where this hysteresis loop is large.

A good example of this is any application where we want a dampening effect, perhaps to absorb and dissipate vibrational energy within a machine, or in the case of rubber engine mounts to absorb the vibration of a car engine. Different materials display different levels of elastic hysteresis. Hard metals, for example, display less hysteresis than high-elongation materials such as elastomers.

Magnetic Hysteresis

Magnetic hysteresis is similar to elastic hysteresis, however instead of changes being caused by applying stress to a material, it’s instead caused by applying a magnetic field.

Applying a magnetic field to a ferrous metal causes the atomic dipoles to align themselves in the direction of the magnetic field. Once we remove the magnetic field part of the alignment will remain in the material, in other words it’s become magnetised.

This property is very important in electrical engineering, in fact it is the basis of how memory works on devices such as hard drives, audio tapes and even credit cards (hence why you should not put a strong magnet near your credit card!)

Keep an eye out for our next articles looking at how we go about selecting engineering materials.

Interested in our courses?

You can read more about our selection of accredited online mechanical and industrial engineering courses here.

Check out individual courses pages below:

Higher International Diploma in Mechanical Engineering

Higher International Certificate in Mechanical Engineering

Diploma in Mechanical Engineering

Diploma in Mechanical Technology

Higher International Diploma in Industrial Engineering

Higher International Certificate in Industrial Engineering

Diploma in Engineering Management

Alternatively, you can view all our online engineering courses here.

Recent Posts

Essential Formulas for Calculating Drilling Parameters

Essential Formulas for Calculating Drilling Parameters When it comes to precision and efficiency in manufacturing, few processes are as foundational—or as critical—as drilling. Whether you’re a seasoned engineer or a student entering the world of mechanical or industrial engineering, understanding how to correctly calculate drilling parameters can significantly impact the quality of your work, the […]

From Raw Material to Refined Component: The Role of Drilling and Turning

From Raw Material to Refined Component: The Role of Drilling and Turning Secondary processes are used in manufacturing to further modify the output of primary manufacturing processes in order to improve the material properties, surface quality, surface integrity, appearance and dimensional tolerance. In this blog, we will focus on drilling and turning as secondary manufacturing […]

Behind the Cutter: How Milling Shapes the Future of Manufacturing

Behind the Cutter: How Milling Shapes the Future of Manufacturing Secondary processes are used in manufacturing to further modify the output of primary manufacturing processes in order to improve the material properties, surface quality, surface integrity, appearance and dimensional tolerance. In this blog, we will focus on milling as a secondary manufacturing process. Machining refers […]