Material deformation techniques

This article discusses various methods where materials are forcibly deformed, and their physical or microstructural properties are altered. This is done to enhance certain mechanical or electrical properties.

The deformation usually takes place at high or low temperatures, and this is reflected in the naming of the process.

Cold Working

This process is often referred to as strain hardening or work hardening. It is a process that involves plastic deformation of a material under cold temperatures.

The plastic deformation occurs when a material is stretched beyond its elastic limit causes a ductile metal to become harder and stronger, increasing properties such as yield strength and maximum tensile stress.

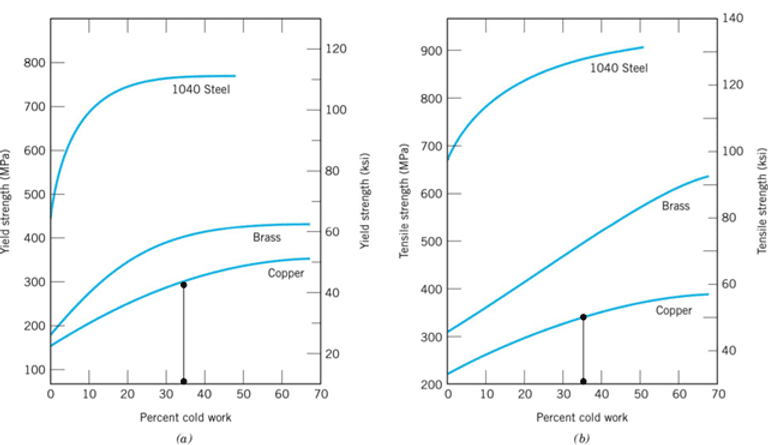

The impact of cold working can be seen in the graphs below.

The first graph (a) shows how the yield strength changes as the percent of cold work increases.

for each material we can see an increase initially, but this then levels off, we can see that the impact for 1040 Steel is far greater than Brass and Copper.

The second graph (b) shows how the tensile strength changes as the percent of cold work increases.

We can see that while the tensile strength increases as the percentage of cold work increases, for 1040 steel and Copper the increase levels off but for Brass it is close to a linear relationship.

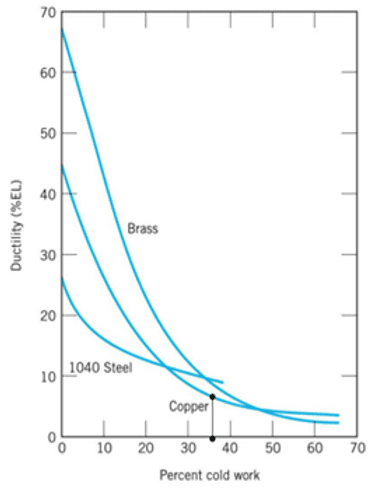

We can see from this graph that the ductility decreases as the percent of cold working increases, in all three materials there is a rapid decrease followed by a plateau.

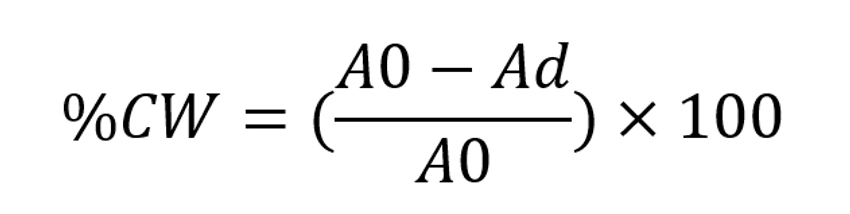

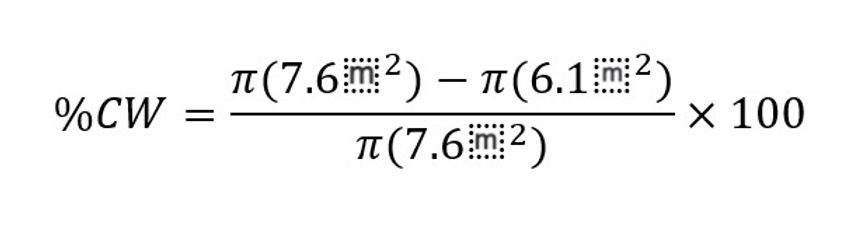

This represents the degree of plastic deformation that occurs during the process. The percentage of cold work is given by:

Where A0 is the area of the cross section that experiences deformation and Ad is the area after deformation.

The graphs above show a significant increase in tensile and yield strength for all materials as well as a large reduction in the ductility.

How does cold working change the properties?

The mechanism behind the cold working process can be explained based on dislocations and dislocation strain fields.

- As the material is deformed under the process of cold working the number of dislocations present in the atomic structure increases.

- Dislocations are formed at grain boundaries, free surfaces, and at the interfaces between the lattice matrix and second phase particles.

- This causes the average separation distance between dislocations to decrease.

Another way to express this is to say the dislocation density within the material is increasing. As the dislocation density within the material increases, and as they are closer together, the motion of the dislocations is hindered, creating a resistance to dislocation motion from other dislocations. The overall effect being that it is harder to deform the material after this process takes place.

Although work hardening may be beneficial as it improves the surface finish, strength properties, dimension control and reduced directional properties, it must be noted that it also has various disadvantages. Hence industries such as those that utilize metal parts, such as boilers, should be aware that the process of cold working may result in reduced ductility, a higher force needed for deformation, strain hardening and unwanted residual stress.

Methods of cold working

There are many ways a metal can be cold worked, such processes are classified by four main categories: squeezing, bending, shearing, and drawing.

Squeezing

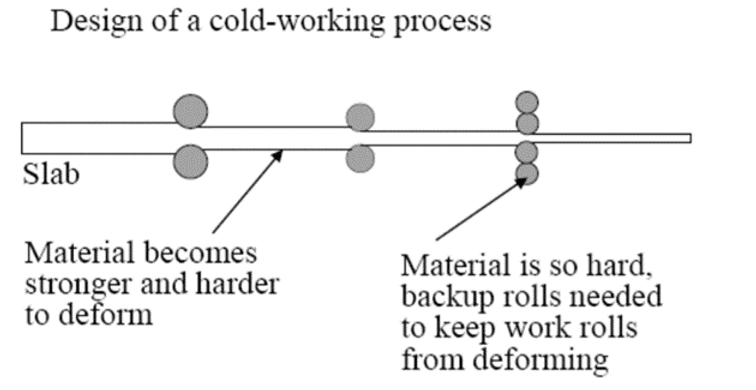

We are going to consider two different squeezing methods, Rolling and Preening

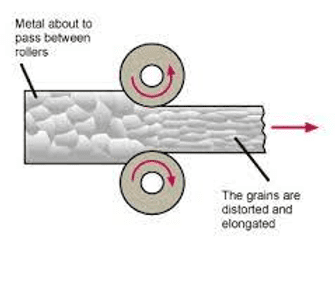

Rolling is classified according to the temperature of the metal rolled.

If the temperature of the metal is above its recrystallization temperature, then the process is known as hot rolling.

If the temperature of the metal is below its recrystallization temperature, the process is known as cold rolling.

Recrystallisation is a process accomplished by heating whereby deformed grains are replaced by a new set of grains that nucleate and grow until the original grains have been entirely consumed.

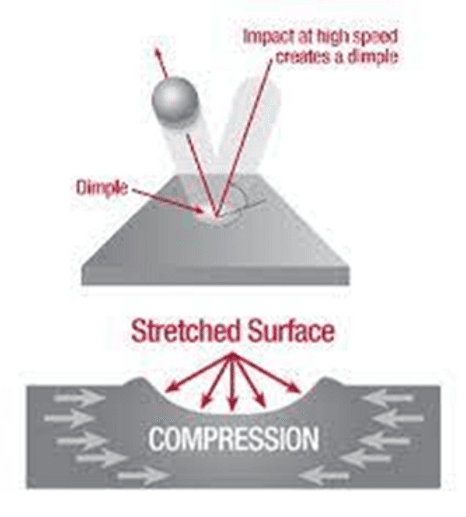

Peening refers to impacting the material in some way, sometimes with a hammer or similar device.

Shot peening is also the method of blasting many small ball bearings at the surface of the material. This causes the surface of the material to become stretched and causes compression within the peened area of the material.

The peened surface gives the material resistance to fatigue, as cracks are less likely to form in the compressed area.

Example:

Work out the percentage of cold working on a cylindrical copper rod if it is coldworked such that the diameter decreases from 15.2mm to 12.2mm. The area depends on the radius so we use 15.2/2 = 7.6 and 12.2/2= 6.1

Solution:

%CW = 35.6%

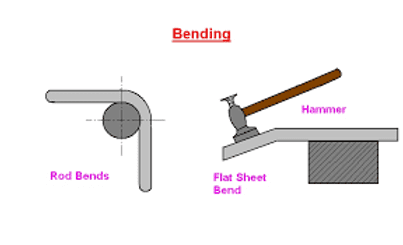

Bending

In this process sheet metal is deformed over a work axis, thereby creating a change in the geometry of the metal. In this process only the geometry of the material is changed but the volume remains constant. When bending is performed, the residual stresses cause the material to spring back towards its original position, so the sheet must be over-bent to achieve the proper bend angle.

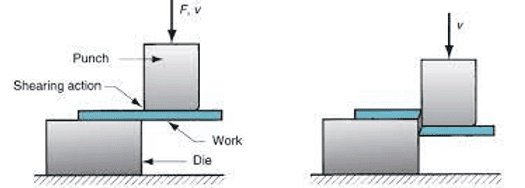

Shearing

Shearing is a metal forming technique sometimes referred to as die-cutting.

In this method, the metal sheet, or flat metallic plates, generally having a thickness of less than 6 mm, are applied with the presser to induce a variety of stress so that the metal can be cut.

Shearing includes several processes like punching, blanking, notching, nibbling, shaving, etc. In the shearing process, there are two blades i.e., upper blade and the lower blade and between these two blades the strip is placed, when the upper blade is moving down the sheer force acts on the metal strip.

As bending takes place, cracks start to nucleate which leads to fracture.

The fracture will begin at the weakest point and progress to the next weakest point until the entire workpiece has been sheared; this is what causes the rough edge.

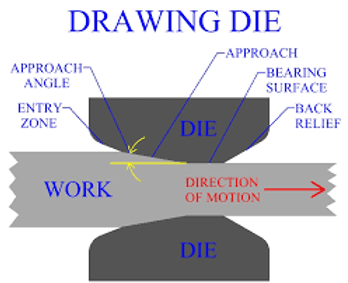

Drawing

Drawing is a metalworking process where tensile forces are applied to a material to elongate it. It is commonly used on metal. glasses and plastics.

As the material is drawn, or pulled, it gradually becomes thinner until its desired thickness and shape is achieved.

Typically, there are two categories including sheet metal drawing and tube drawing. In tube drawing materials are drawn through a small hole, or die, to decrease the diameter and increase length. Materials formed in this way include steels, aluminium alloys, and copper alloys.

Annealing

Annealing is a generic term that is applied to materials that undergo heat treatment.

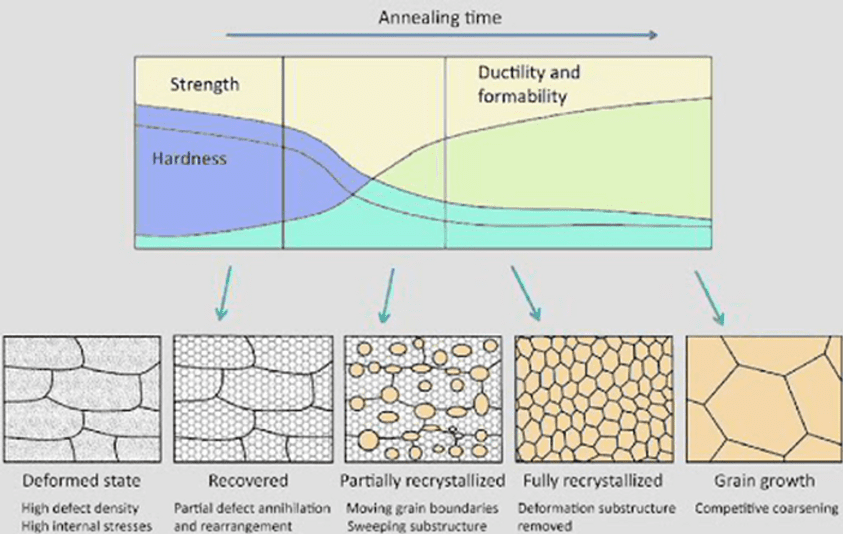

Previously, we examined how cold working can change the microstructural properties of a material. This led to an increase in the strength of the material and a reduction in ductility. The properties and structures of the material may revert to the pre cold worked states by appropriate heat treatment, or annealing. The resulting restoration occurs in three stages, recovery, recrystallisation and grain growth.

The annealing process takes place in essentially a large oven. Where the material is exposed to high temperatures and circulating air.

Recovery stage

During the recovery stage some of the stored internal strain energy is relieved via increased dislocation motion from the enhanced atomic diffusion at elevated temperatures.

There is a reduction in the overall number of dislocations in the material resulting in a softer material. Properties such as electrical and thermal conductivities are increased or recovered to pre cold worked states.

The more ductile material is now more workable and can be shaped more easily.

Crystallisation stage

After recovery recrystallisation occurs, which is the formation of a new set of strain free grains within the material.

These grains have a lower dislocation density and return to those of the original state.

The new grains grow from small nuclei and eventually replace the parent material.

The material now becomes softer and weaker but regains some of its ductility. Figure 4 demonstrates how the properties of the material change during the recrystallisation process.

Grain Growth

The final stage of the annealing process is grain growth. Grain growth does not necessarily have to be preceded by recovery and recrystallisation and can occur in polycrystalline, metals and ceramics.

As grains increase in size the grain boundary area decreases. The grain growth occurs due to the migration of grain boundaries over time, which is essentially just atomic diffusion of atoms from one side of the boundary to the other.

Higher temperatures and time left at this temperature will result in larger grain sizes.

Online Engineering Courses and Qualifications

Are you interested in learning more about engineering materials?

Do you want to earn an accredited diploma qualification in engineering?

Check out our range of fully accredited online engineering courses and diplomas to gain a formally recognised engineering qualification.

Why not check out the online engineering short courses specifically in manufacturing engineering:

Recent Posts

A Quick Guide to Thermal Stress

A Quick Guide to Thermal Stress Thermal expansion and the resulting thermal stress are key concepts in engineering and physics. They describe how materials expand or contract when exposed to temperature changes. Understanding these principles is essential for designing structures and systems that can withstand environmental fluctuations without failure. What is Thermal Expansion? When materials […]

How to Calculate Shear Stress

Introduction to Shear Force and Shear Stress Shear force and shear stress are critical concepts in mechanics and materials science, often encountered in structural engineering and manufacturing. Shear Force refers to the internal force in a material that acts parallel to its cross-section. It is measured in Newtons (N). Shear force arises when two opposing […]

Kirchhoff’s current and voltage laws

Kirchhoff’s current and voltage laws In our last article, we looked at the principles and operation of a d.c motor. In this article, we’re going to investigate Kirchoff’s current and voltage laws, as well as how to apply them to engineering problems. Kirchoff’s law of current Kirchoff’s law of current states that the algebraic sum […]