Engineering Materials…What ‘stuff’ is made from

Engineering can be defined as the application of science and technology to create or produce something of use.

In order to ‘produce’ something, we need to process or ‘form’ some sort of material into a useful ‘shape’ or combination of shapes. In order to do this, we need to understand what materials are, and how they can be processed and shaped.

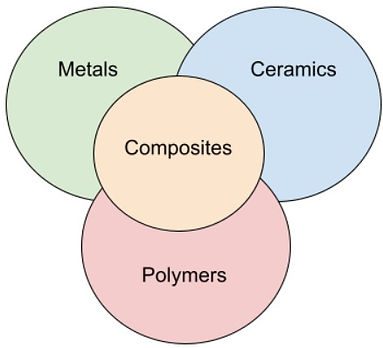

Broadly speaking, engineering materials can be broken down into 4 distinct groups.

- Metals

- Polymers

- Ceramics

- Composites

Metals

Metals are the largest group of materials, and are involved in the majority of engineering applications. Metals can be subdivided into two major families, ferrous and non-ferrous. Ferrous simply means that the material ’contains iron’, so a ferrous metal is one which contains iron in some way, whilst a non-ferrous metal does not.

The primary bonding method between metals is metallic bonding, and the structural arrangement of most metals can be grouped within one of several crystalline structures.

Example of a Ferrous Metals

Steel

At its most fundamental, steel is an alloy of iron and carbon. There are many different grades of steel depending on the levels of carbon added to the iron (it typically ranges from 0.3% up to 1.5%).

Additionally alloying other elements such as chromium, nickel or titanium can be used to manufacture steel with a range of properties, such as increased strength, or durability but without increasing its weight.

In general, increasing the levels of carbon added, subsequently increases the steels strength and hardness, whilst decreasing its ductility.

Examples of Non-Ferrous Metals

Aluminium Alloys

Pure aluminium is relatively weak and soft, not much use as an engineering material! However once it is mixed with other materials (i.e. an alloy) you can then start to increase its strength. The pure aluminium does have good corrosion resistance due to an oxide coating that forms over the material and prevents oxidation, this is a positive property that the aluminium brings, but you must be careful as alloying the aluminium tends to reduce its corrosion resistance.

Aluminium is a widely used material and particularly in the aerospace industry due to its light weight and corrosion resistance. Although aluminium alloys are generally not as strong as steels, they have a very good strength-to-weight ratio (in fact they will often exceed steel in a strength-to-weight ratio). Perfect for making large components such as aircraft wings or fuselages.

Titanium Alloys

Titanium alloys are light, strong, and have high corrosion resistance. Their density is much lower than steel, and their strength-to-weight ratio is excellent. In fact, Titanium has an excellent mixture of high strength, stiffness, toughness, lightness, and resistance to corrosion over a range of temperatures makes it an excellent choice for many aerospace structures.

Of course there is a downside! And that is the relatively high cost of titanium alloys compared to other materials.

Polymers

The term ‘polymer’ encompasses a vast range of biological and synthetic materials that are used in a wide range of applications. The market for polymers involves many large commercial organisations that compete with one another in different market sectors.

Thus, polymer names involve chemistry, from various eras, plus commercial trade names, all of which are used synonymously. The vast majority of the items we call ‘plastic’ are made from one of five ‘families’:

1. PE: polyethylene (low density = LDPE, high density = HDPE), e.g. carrier bags.

2. PP: polypropylene, e.g. drinks cups, kettles, shampoo bottles

3. PS: polystyrene and expanded polystyrene (EPS), e.g. insulating cups, packaging

4. PVC: poly(vinyl chloride), e.g. window frames, insulation cables for domestic wiring.

5. PET: poly(ethylene terephthalate), e.g. transparent water bottles.

The primary molecular bonds are covalent bonds between long chains of C-C atoms. However secondary bonding acts between the groups of polymer chains to form the polymeric material.

Ceramics

Ceramics are a combination of elements which are atomically bonded together, and may consist of metallic or nonmetallic elements. Ceramics can be classified by their composition, that is the bonding element. Typical examples of ceramics are oxides (use of oxygen), nitrides (use of nitrogen), or carbides (use of carbon).

The primary types of ceramics include glasses, cements, clay products, hard tooling materials, and abrasives.

Due to the strong ionic bonding between the metal and bonding element above, ceramics generally have very high melting points, and are very hard with high stiffness. They also have excellent corrosion and wear resistance, and low electrical and thermal conductivity. Ceramics are very brittle materials.

One very common application of ceramics is the use of tungsten carbide in carbide drill bits. This makes a drill bit very tough and hard-wearing. Perfect for drilling steel and other metals without itself wearing down too quickly.

Composites

In materials terms, anything which is made of multiple materials (which are not atomically bonded) is known as a composite. One good example being steel reinforced concrete, where steel rods are inserting into concrete to add additional strength to a structure.

Let’s take a look at one of the most common engineering applications of composites; carbon-fibre reinforced polymers (CFRP).

Carbon-Fibre Reinforced Polymers (CFRP)

CRFP is a material made up of very thin strands of carbon fibre, embedded into a plastic matrix (generally a type of epoxy resin).

The fibres carry most of the stress, and the matrix serves to hold the fibres in place and to transmit stress between the fibres. The fibres can be short and randomly oriented, or they can be long and continuous.

The result is a very lightweight and strong material, which is widely used in the aerospace and automotive industries.

One distinct advantage of CFRP as an engineering material, is that it can be designed to carry load in a specific direction by managing the direction of the fibres. This can be particularly useful in aerospace applications, where load is only required in a specific direction (such as the bending of a wing). In these situations the fibres can be oriented to carry strength only in the direction that is needed, and hence can result in a very optimised solution.

Summary

In summary almost everything manmade that you see around you has been manufacturing from one of the four materials groups discussed above. The below summary table acts as a good guide when it comes to picking the right materials for each application.

Interested in electrical and electronic engineering? Find out more about all the electrical engineering courses we have available by clicking here.

Diploma in Electrical Technology

Diploma in Renewable Energy (Electrical)

Diploma in Electrical and Electronic Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Dynamic Effects of Linear Motion

Dynamic Effects of linear Motion Variable Acceleration Depending on Time In Engineering, motion is often analysed through quantities like displacement, velocity, and acceleration. While many introductory problems assume constant acceleration (like free-fall near Earth’s surface), real-world motion is frequently more complex. One important case is when acceleration changes with time, this is known as variable […]

How to Calculate Bending Stress

How to Calculate Bending Stress When a beam is subjected to loading acting on a plane passing through the beam’s axis, the beam deforms, or ‘bends’. The beam reacts to the external loads with the internal shear force and bending moments. Bending stress is a fundamental concept in structural engineering and mechanics of materials. It […]

A Quick Guide to Thermal Stress

A Quick Guide to Thermal Stress Thermal expansion and the resulting thermal stress are key concepts in engineering and physics. They describe how materials expand or contract when exposed to temperature changes. Understanding these principles is essential for designing structures and systems that can withstand environmental fluctuations without failure. What is Thermal Expansion? When materials […]