How to calculate stress for direct loading of components.

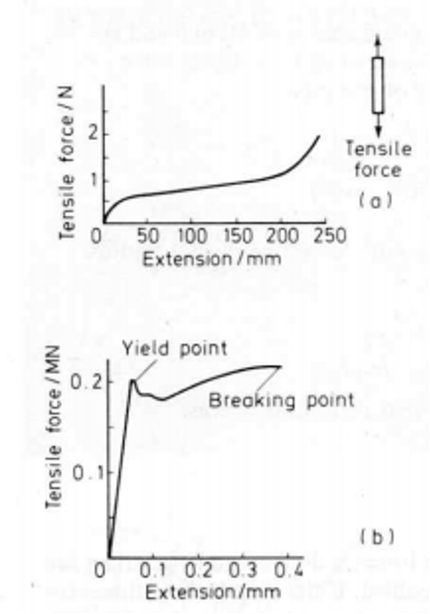

If a rubber strip is pulled it stretches, and the more you pull it the more it stretches. There’s a relationship between the extension and the force applied, known as Hooke’s Law, and it can be expressed as a force extension graph:

The top graph above shows the graph we’d see for a strip of rubber, and the bottom graph shows a piece of steel. You’ll notice that the forces needed to stretch steel are considerably greater than for rubber. We can also see, from looking at the extension axis, that the amount by which rubber changes length is greater than that of steel.

You can also see that the overall shapes of the graphs are very different. The rubber, after a small force, needed very little increase in force to produce greater extensions. After an extension of about 200 millimeters, the rubber becomes much more difficult to stretch. The steel needs quite large forces to produce any extension. However, when the force reaches 0.2 MN (0.2 x 106), the steel increases considerably in length without any more force being applied. The steel is said to have yielded.

Force Applied Calculation

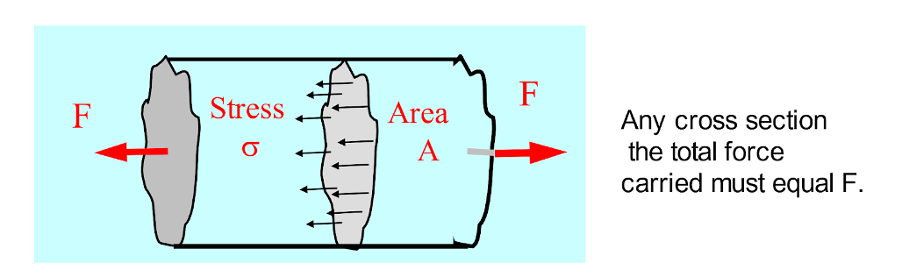

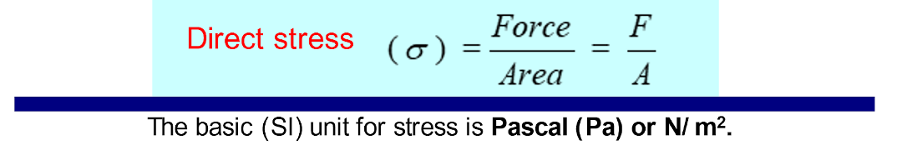

The force is applied to the rubber and the steel strips, resulting in an increase in the lengths of the strips. The forces are said to be tensile forces and the strips are in tension. If the cross-sectional area of the strip is doubled, then twice the forces are needed to give the same extension. If the cross-sectional area is 3 times larger, then the force must be three times larger to get the same extension. For the same extension, the force per unit area should be constant. This quantity is called stress:

stress=force area

σ=FA

Where F is the force (N) and A is the area (m2). The units of stress are N/m2 or Pa (1 Pascal = 1N/ m2).

Direct or Normal Stress.

Look at the image below, with a bar of length L. Constant cross-sectional area A is subjected to an axial tensile force F.

When the force is uniformly distributed over the section, then:

The stress is said to be direct stress when the area being stressed is at right angles to the line of action of the force, as is the case as shown with the rubber graph above.

Let’s look at an example. A specimen with a cross-sectional area of 50mm2 was subjected to a tensile force of 0.1 MN. We’re going to calculate the stress induced in this specimen.

Firstly, we convert the values to SI units:

1mm2 = 0.001 x 0.001m2 = 1 x 10 – 6m2

Therefore, 50mm2 = 50 x 10 = 6m2

σ=FA=0.1x10650x10-6=2×109=2GPa

Keep an eye out for more of our articles where we dive deeper into some of these concepts.

Interested in our courses?

Interested in civil or mechanical engineering? Find out more about all the civil engineering courses we have available by clicking here, and the mechanical engineering courses by clicking here.

Diploma in Mechanical Engineering

Diploma in Mechanical Technology

Diploma in Sustainable Construction

Diploma in Structural Engineering

Diploma in Building and Construction Engineering

Higher International Certificate in Civil Engineering

Higher International Diploma in Civil Engineering

Higher International Diploma in Mechanical Engineering

Higher International Certificate in Mechanical Engineering

Alternatively, you can view all our online engineering courses here.

Recent Posts

Aircraft Basics: Main Components and Standard Control Surfaces Explained

Aircraft Basics: Main Components and Standard Control Surfaces Explained Introduction In this blog we will identify the main components within an aircraft, more from the point of view of large external parts, more specifically, flight control surfaces. Flight control surfaces are simply physical devices that the pilot can control and adjust in order to change […]

Understanding and Calculating Generator Efficiency and Output Parameters

Understanding and Calculating Generator Efficiency and Output Parameters Introduction The performance of a generator is often judged by how efficiently it converts mechanical energy into electrical energy. Understanding and calculating this efficiency, along with other key output parameters such as voltage, current, power factor, and load, is essential for evaluating performance and ensuring reliable operation. […]

Essential Cooling and Protection Devices: How They Work and Why They Matter

Essential Cooling and Protection Devices: How They Work and Why They Matter Introduction Generators produce a significant amount of heat and electrical stress during operation, which can affect performance and lifespan if not properly managed. That’s where cooling and protection devices come in. These essential systems, including fans, radiators, circuit breakers, and relays, work together […]