How does the grain size affect the strength of a material?

In this article we are going to focus on how the grain size impacts on yield strength.

What is a grain?

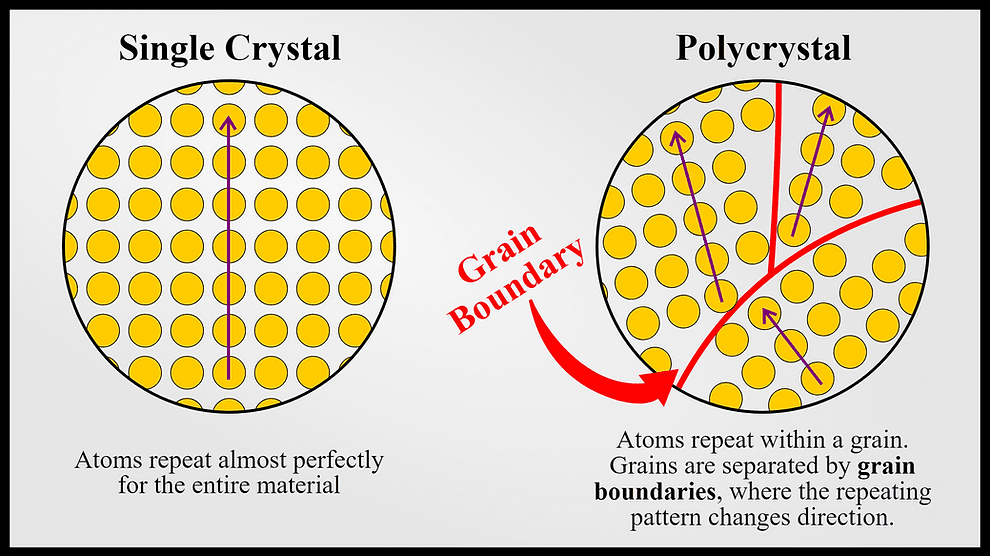

A crystal can be modelled as a unit lattice in which atoms are arranged in a specific position, when a group of crystals are arranged in the same direction they form a grain.

As the small crystals grow, they form more grains and eventually form a polycrystalline structure.

A grain boundary is the interface between two grains, or crystallites, in a polycrystalline material and are considered two dimensional defects in the crystal structure.

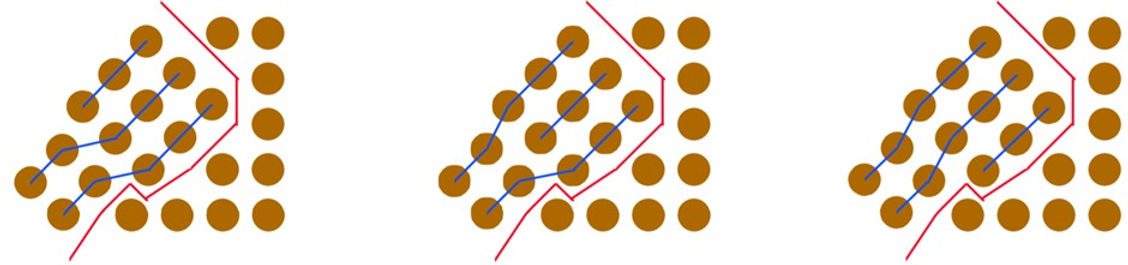

When exposed to stress and thermal energy, dislocations move through the grains of a material,

resulting in permanent distortion of the grain itself.

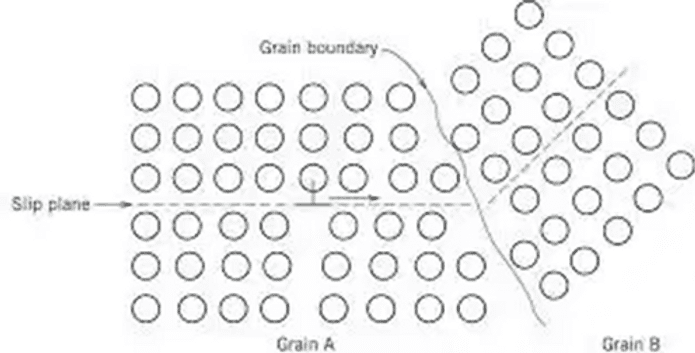

When a dislocation reaches a grain boundary it is prevented from continuing.

In the diagram above the blue lines represent the dislocations and the red lines are the grain boundary

How do grain boundaries act stop dislocation motion?

There are two primary ways in which grain boundaries can act as a boundary to dislocation motion.

Firstly, since the grains are of different crystallographic orientations, if a dislocation passes from one grain to another it will have to change its direction of motion.

Secondly, the atomic disorder within a grain boundary region results in a discontinuity of slip planes from one grain into the other. A slip is described as the displacement of one part of a crystal relative to another part along crystallographic planes and directions.

If we can stop dislocations then less deformation will take place, this will strengthen the material.

If we want to strengthen the material we need to increase the size or amount of grain boundary, the amount of grain boundary is linked to the size of the grains.

Smaller grains have greater ratios of surface area to volume, which means a greater ratio of grain boundary to dislocations. The more grain boundaries that exist, the higher the strength becomes. The concept is hard to visualise, so the following concept can be visualised in the diagram above.

Surface area to volume ratio

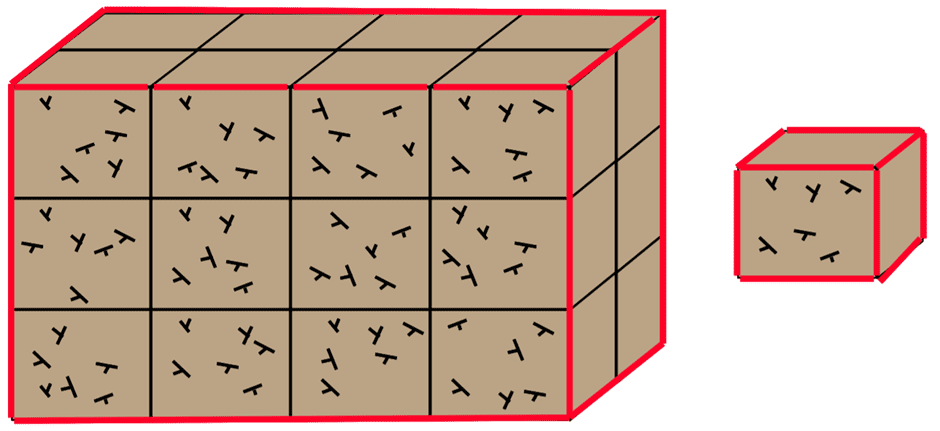

The diagram below is a representation of two grains. To simplify the calculations we will use a the red outlines of each rectangular prism to represent the grains.

Each prism is made up of several cubic units. For the sake of this analysis, each unit contains exactly six dislocations (small black t shapes).

- For the larger grain, there are 2 x 3 x 4 = 24 cubic units, which will have 24 x 6 = 144 dislocations

- For the smaller grain is 1x1x1 = 1 cubic unit. and the smaller grain has 1 x 6 = 6 dislocations.

- The larger grain has a total surface area of 2 x (2 x 4) + 2 x (2 x 3) + 2 x (3 x 4) = 52 square units.

- The smaller grain has a surface area of 6 x(1×1) = 6 square units.

The surface area represents the amount of grain boundary in this instance.

- For every dislocation in the large grain, there is 52/144 = 0.36 square units of grain boundary

- In the smaller grain, there is 1 square unit of grain boundary for each dislocation

Calculated by the number of units divided by the number of dislocations.

Conclusion

There is a much greater chance for a dislocation to be stopped at a grain boundary in the smaller grain. Therefore, the smaller grain is stronger.

In the larger grain, a dislocation can travel up to 4 units without being stopped by a grain boundary, indicating the potential for extensive plastic flow.

In the small grain, no dislocation can travel more than 1 unit of distance.

In the final section we will see how the yield strength is directly related to the diameter of the grain.

Hall-Petch equation

The yield strength of a material can be approximated using the Hall-Petch equation, although this equation is not applicable for extremely fine or coarse grains.

Where

k is a constant, d is the average grain diameter, and σ0 is the original yield stress.

Note that this equation is invalid for very large (i.e., coarse) grain and extremely fine-grain polycrystalline materials.

This mathematical relationship shows that as the grain diameter increases the yield strength decreases.

There are several different methods for achieving the desired fine grain in metals.

- Thermal refinement involves controlling the cooling rate of melted aluminium.

- Promoting a rapid cooling rate while varying the solidification process allows for the desired fine microstructure.

- You can also use a mechanical method where the melted metal is agitated during the solidification phase. Special devices using electromagnetic, ultrasonic, and mechanical stirrers are placed into the aluminium when it is in a semisolid state.

Online Engineering Courses and Qualifications

Are you interested in learning more about engineering materials?

Do you want to earn an accredited diploma qualification in engineering?

Check out our range of fully accredited online engineering courses and diplomas to gain a formally recognised engineering qualification.

Why not check out the online engineering short courses specifically in manufacturing engineering:

Recent Posts

Kirchhoff’s current and voltage laws

Kirchhoff’s current and voltage laws In our last article, we looked at the principles and operation of a d.c motor. In this article, we’re going to investigate Kirchoff’s current and voltage laws, as well as how to apply them to engineering problems. Kirchoff’s law of current Kirchoff’s law of current states that the algebraic sum […]

What are the principles of operation of a DC electric motor?

What are the principles of operation of a DC electric motor? In our last article, we looked at the electrical parameters in series and parallel electrical circuits. In this article, we’re going to dive into the principles of operation of a DC electric motor. The motor effect When a current-carrying conductor is placed on a […]

What are the electrical parameters in series and parallel electrical networks?

What are the electrical parameters in series and parallel electrical networks? In our last article, we looked at the principles of operation of electrical cells. In this article we’re going to move on to the electrical parameters in both series and parallel electrical networks. When we have circuits with more than one resistor, we need […]